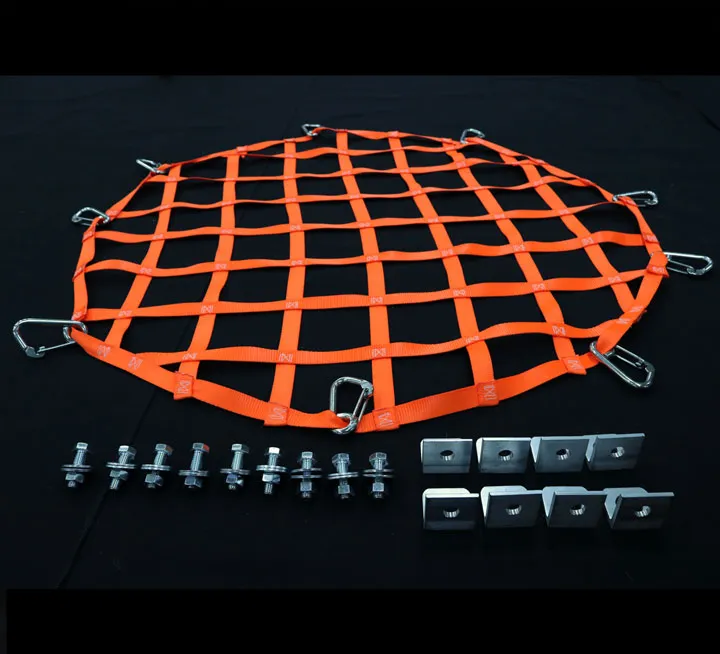

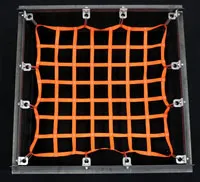

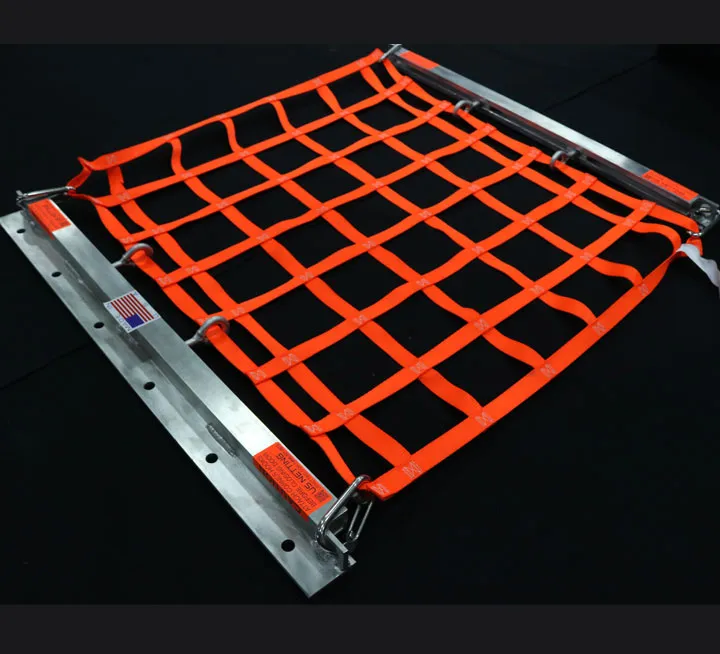

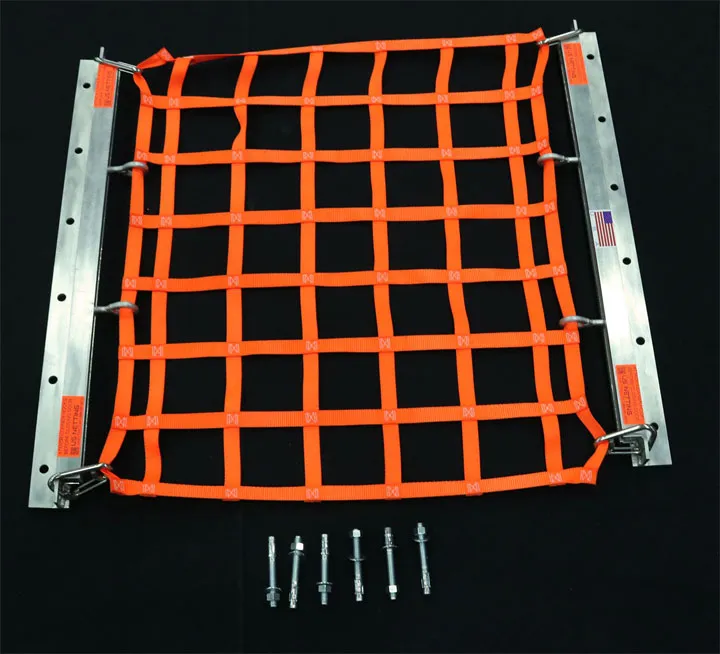

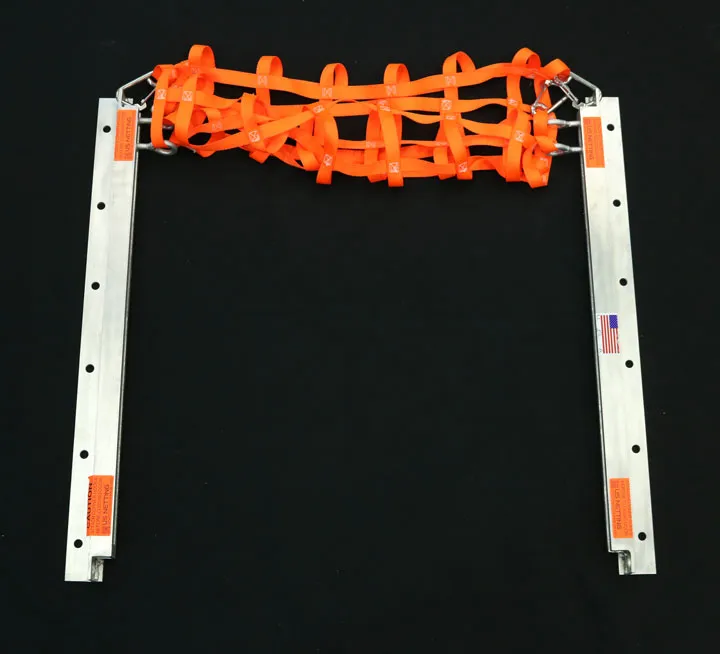

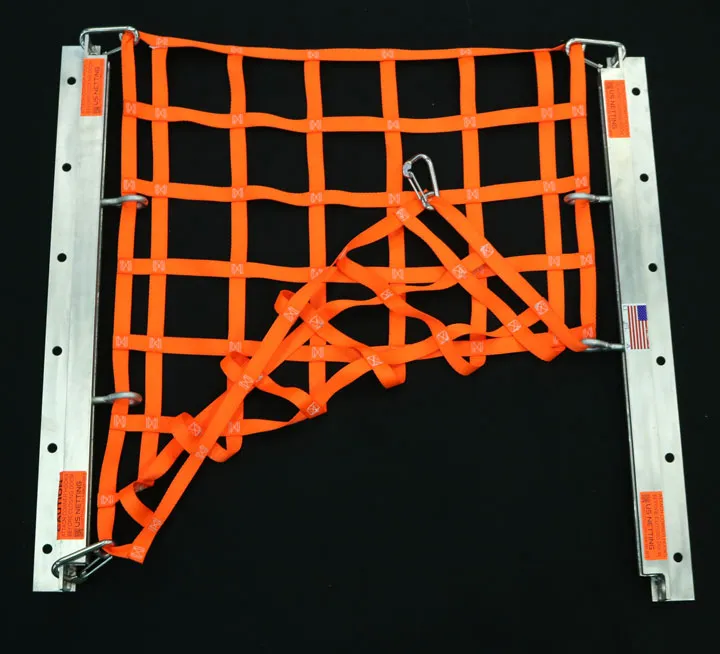

Main Features:

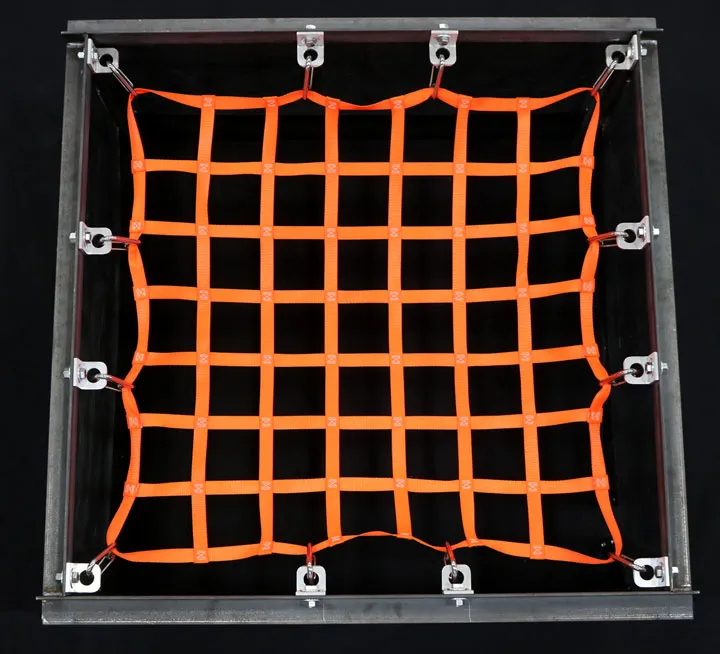

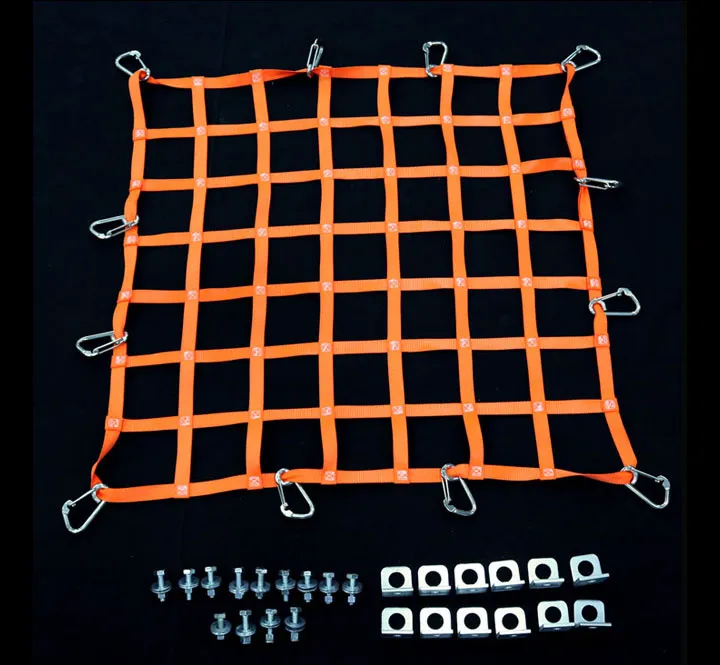

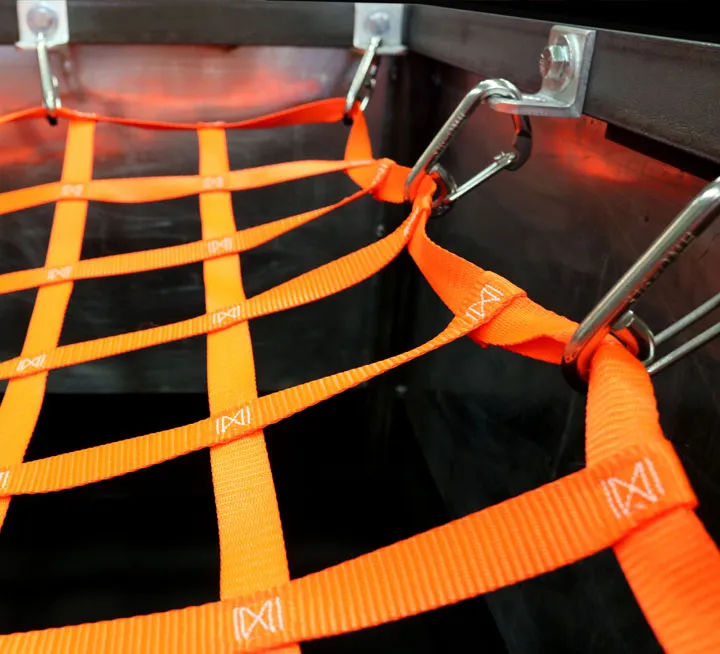

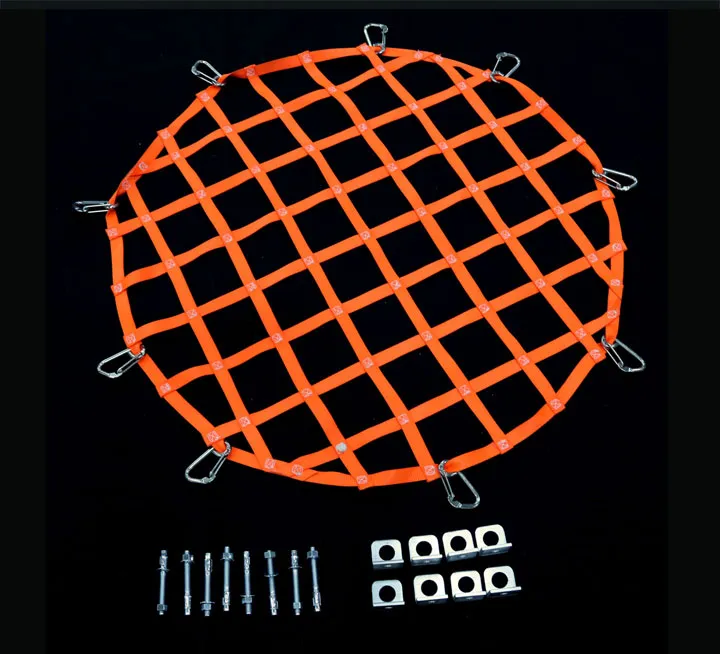

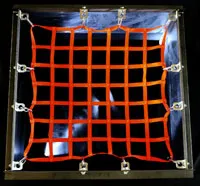

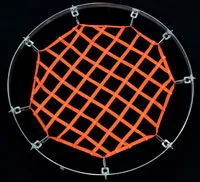

- Quickly installs in a roof or floor opening

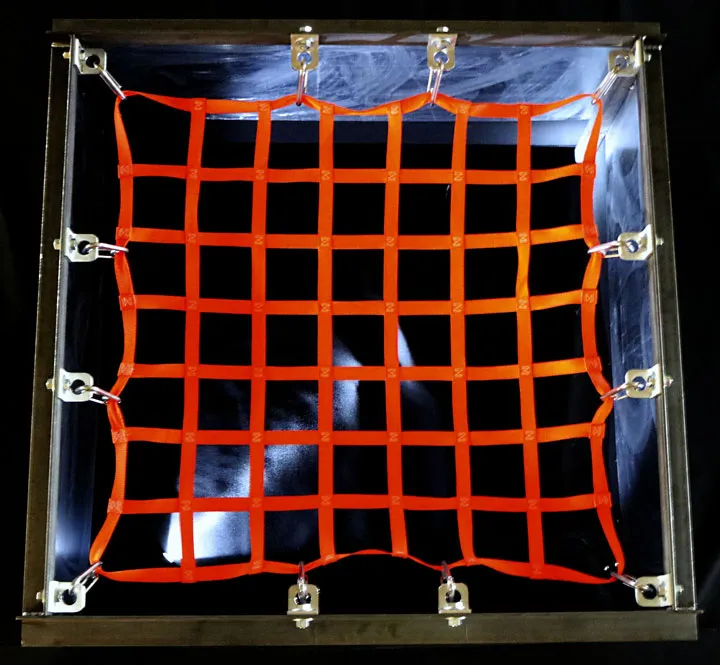

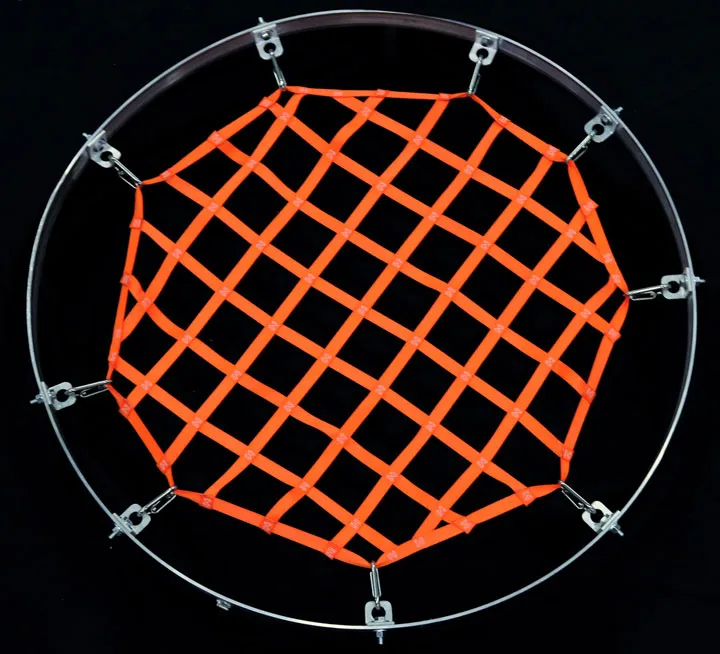

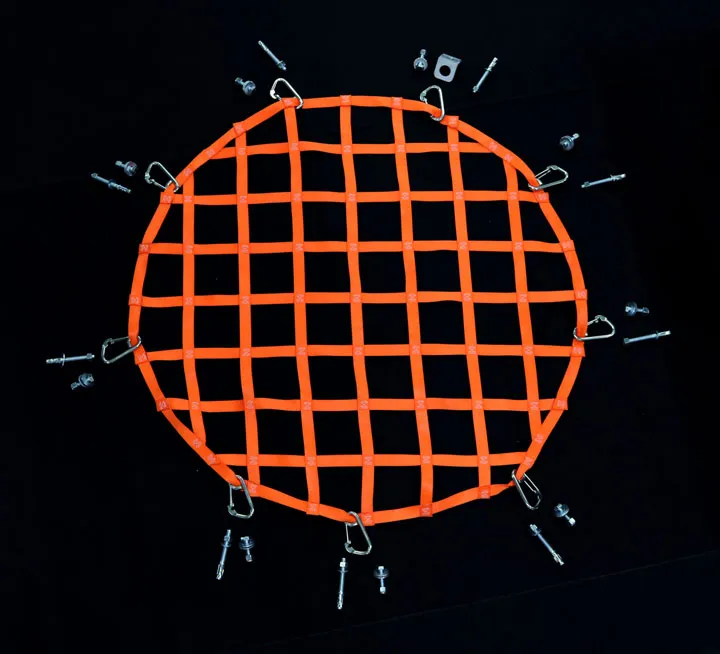

- Custom made to fit a new or existing application

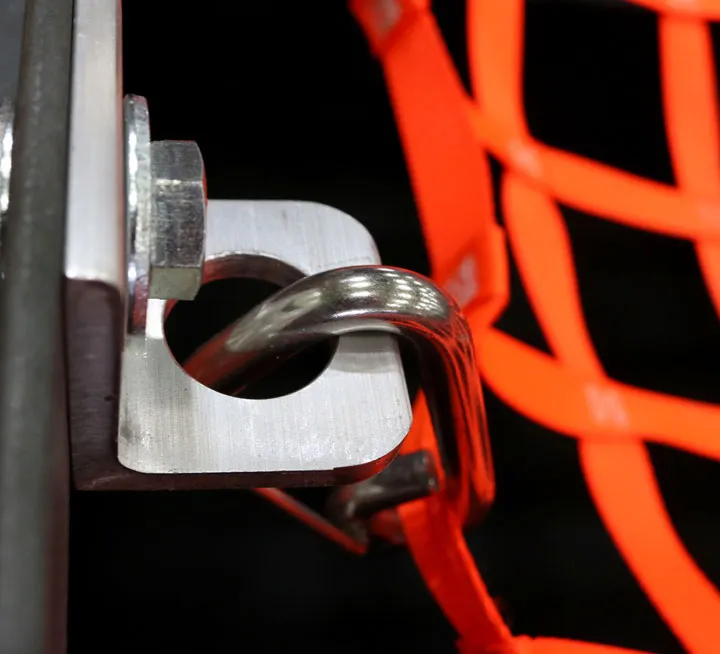

- 2" x 2" x .25" thick 304 Stainless Steel Brackets

- Full 5-year warranty (see below)

- Enhances employee safety

- Allows freedom of movement

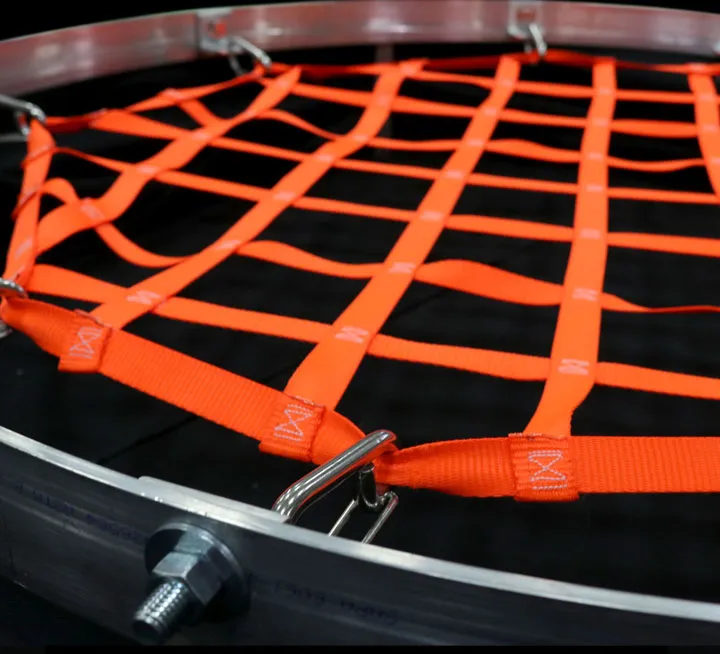

- Offers full visibility of the area below the hatch net

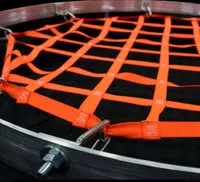

Hatch Net Description:

The hatch netting fall-thru protection system drastically reduces the risk of death or injury from a fall-thru in hatch installations. The hatch net meets and/or exceeds applicable OSHA and ANSI regulations (see below). Our fall-thru prevention system is lightweight and can be installed in any type of floor or roof access. Perfect use on retro-fit or new units. US Netting can construct a hatch net in all shapes and sizes.