Loading Dock Safety Equipment Engineered to Exceed OSHA Requirements

Why is loading safety important?

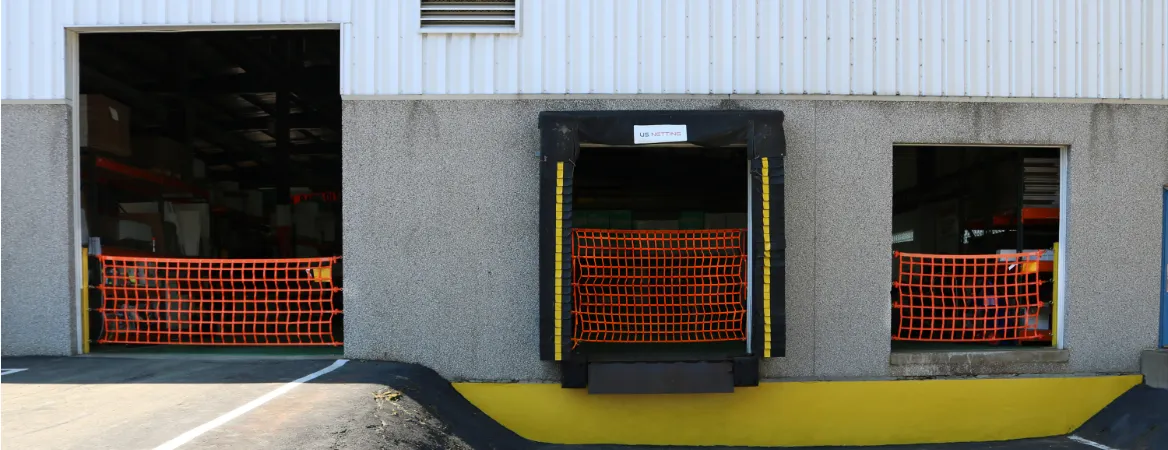

A loading dock zone is an area in any warehouse where freight trucks load and unload products. Loading docks come in one of two styles. They either have a four-foot drop or a cement ramp, and the door opening is flush with the ground. Loading docks are familiar in any manufacturing or distribution building. Though they are common, there are also many accidents and deaths surrounding loading docks, making them one of the most dangerous aspects of any warehouse.

In 2020, 7,290 forklift accidents resulted in injury, and 78 resulted in death. Additionally, there were 49,250 lower-level fall accidents. Slips and falls around loading docks are too common to ignore. Employee safety is a necessity to ensure a safe workplace environment. Preventing forklift accidents and falls before an accident occurs is a top priority. Developing a system that works best for your warehouse is an effective strategy.

The best time to install a safety system in your warehouse is before an inevitable accident. Yet, it is never too late to focus on safety solutions in your warehouse.

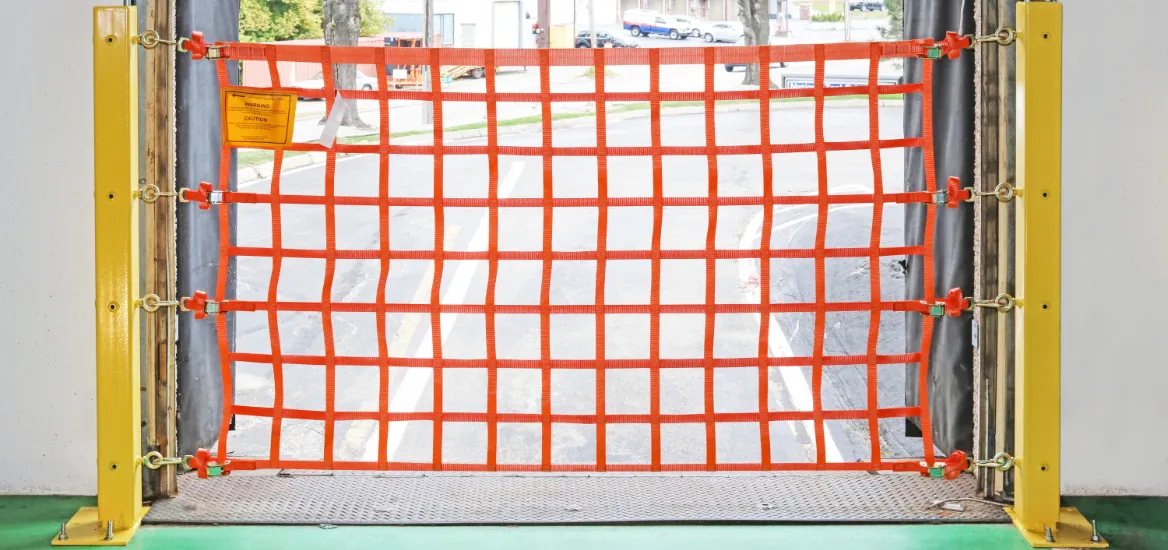

The most common loading dock accidents are slips and falls, which account for 25% of incidents. Loading dock nets are a great way to prevent accidents in a warehouse. They are also a low-cost investment to avoid a $12,000 fine from OSHA. Any loading dock that does not have a safety system qualifies for a fine.

Barrier solutions are effective when they enhance workplace safety and meet OSHA requirements. Required OSHA guidelines are lengthy, in-depth, and overwhelming.

This is why we have read and studied the list to engineer a product that not only meets but exceeds OSHA requirements and regulations.

Understanding why accidents happen helps to determine the best loading dock safety solution.

It is common for warehouses to leave their dock doors open throughout the day. There are many reasons for this. For instance, many warehouses are not temperature controlled.