Warehouse Wednesday: Rack Safety Solutions

Limited storage space is a common issue in warehouses.

The solution? Pallet racking that builds up. Racks that contain equipment, products, tools, and packaging are standard in warehouses. Some warehouse designs provide separation between storage and working areas. While other warehouses integrate a system where workers walk below racks of storage.

This may seem to be an effective solution. Yet, issues lie during the unloading and loading process of the racks. Individuals walking beside a rack face the danger of becoming struck by a falling object. Falling products or equipment could cause serious injury or death.

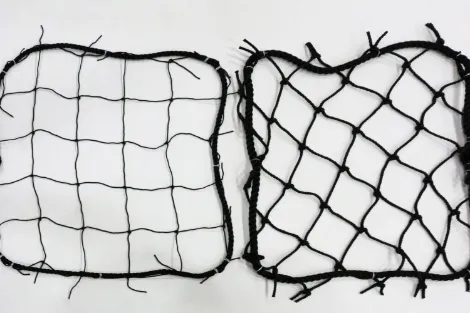

Such accidents are likely to occur during the loading and unloading process. This poses a severe yet preventable risk to safety. Pallet rack guards can prevent the product from falling. Such installation is simple yet is an effective mechanism for avoiding warehouse accidents.