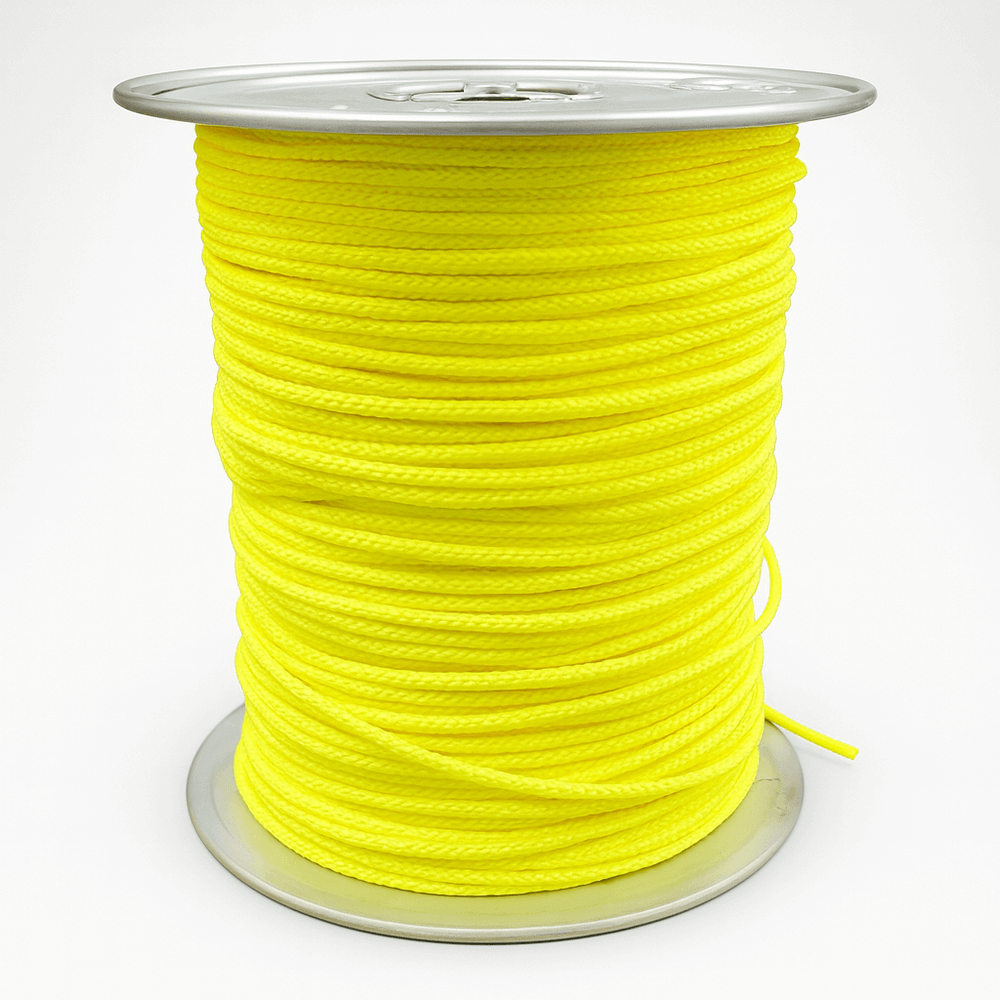

Kevlar™ Core / Diamond Braid Rope

Diamond braid polyester rope with Kevlar™ core for exceptional durability

Description: Heat resistant, high strength, low stretch.

Diamond braid polyester rope with Kevlar™ core for exceptional durability

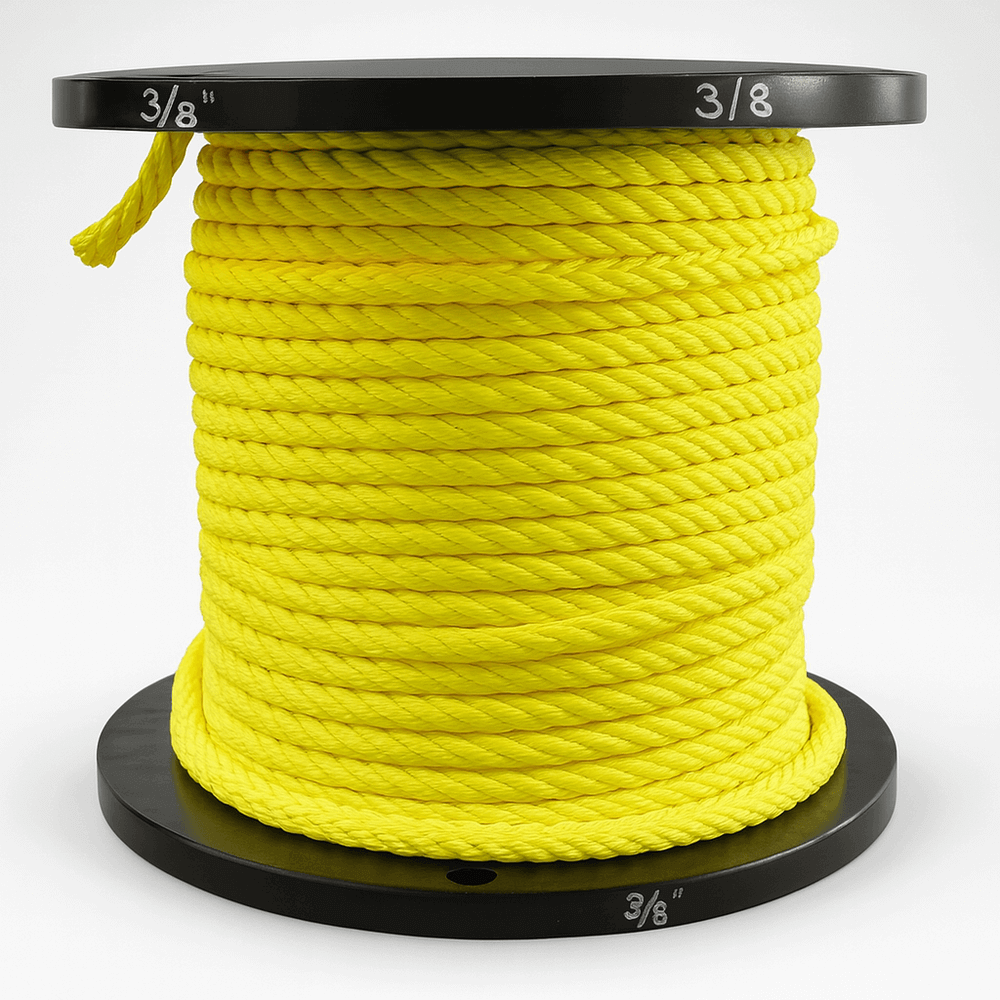

12 strand single braid Kevlar™ rope with exceptional heat and chemical resistance

Discover US Netting's premium Kevlar™ ropes, engineered for extreme strength and heat resistance in the most demanding applications.

US Netting's Kevlar™ ropes deliver unparalleled strength-to-weight ratio with exceptional heat resistance. With a melting point of 930°F and maintaining strength up to 500°F, these ropes excel where others fail. Highly resistant to acids, alkalis, and organic solvents, Kevlar™ rope provides the ultimate solution for extreme environments and critical applications.

Our flagship Kevlar™ rope features a smooth surface with exceptional abrasion resistance. Available from 1/8" to 5/8" diameter with tensile strengths from 2,100 to 39,000 lbs. The 12-strand construction provides flexibility while maintaining incredible strength. Perfect for high-temperature environments and critical lifting operations.

Features a 100% DuPont™ Kevlar™ fiber core surrounded by a protective polyester cover. This construction provides additional abrasion resistance while maintaining low stretch characteristics. Ideal for sensor lines, paving applications, and precision work requiring minimal elongation under load.

Melting point of 930°F with strength retention up to 500°F. Ideal for high-temperature applications.

Highly resistant to acids, alkalis, and organic solvents. Maintains integrity in harsh environments.

Minimal elongation under load with low creep and stress relaxation. Perfect for precision applications.

From foundries to glass manufacturing, Kevlar™ rope maintains strength where traditional ropes would fail. Essential for hot work environments.

Critical applications requiring maximum strength-to-weight ratio. Used in parachute cords, tethers, and safety systems.

Mooring lines and deep-sea applications benefit from Kevlar's strength and resistance to saltwater degradation.

Low-stretch properties make it ideal for architectural rigging, stage rigging, and applications requiring precise positioning.

| Diameter | Construction | Tensile Strength | Weight (per 100 ft) | Working Load (5:1) |

|---|---|---|---|---|

| 1/8" | 12 Strand | 2,100 lbs | 0.8 lbs | 420 lbs |

| 1/4" | 12 Strand | 9,500 lbs | 3.2 lbs | 1,900 lbs |

| 5/16" | 12 Strand | 11,700 lbs | 5.0 lbs | 2,340 lbs |

| 3/8" | 12 Strand | 17,800 lbs | 7.2 lbs | 3,560 lbs |

| 1/2" | 12 Strand | 31,000 lbs | 12.8 lbs | 6,200 lbs |

| 5/8" | 12 Strand | 39,000 lbs | 20.0 lbs | 7,800 lbs |

Kevlar™ rope offers 5 times the strength of steel on a pound-for-pound basis. Unlike nylon or polyester, it maintains strength at extreme temperatures and resists chemical degradation. While more expensive initially, its longevity and performance in critical applications provide exceptional value.

Than steel by weight

Melting point

< 3.5% at break

Get the ultimate in strength and heat resistance. Available in spools or cut to length. Contact our experts at 1-800-331-2973 for custom requirements.

Kevlar™ is a high-performance synthetic fiber that requires complex manufacturing. Its exceptional properties - strength, heat resistance, and durability - justify the investment for critical applications where failure isn't an option.

Yes, but it requires special techniques and should be done by professionals. Splicing can reduce strength by 10-20%, so mechanical terminations are often preferred for critical loads.

With proper care and avoiding UV exposure, Kevlar™ rope can last 10-15 years or more. Regular inspection is crucial as damage may not be immediately visible.

While Kevlar™ has excellent strength, it's sensitive to UV radiation. For prolonged outdoor use, choose our versions with protective coatings or covers, or consider covered storage when not in use.