Maximize the Life of Your Netting

Spring Maintenance Guide: Enhancing the Lifespan and Performance of Your Business's Netting Systems

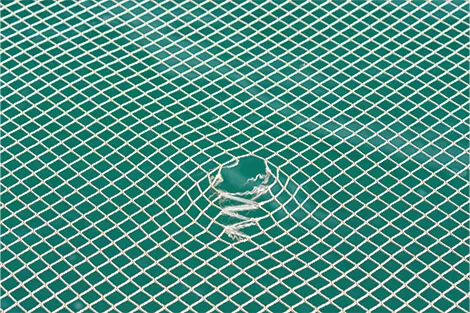

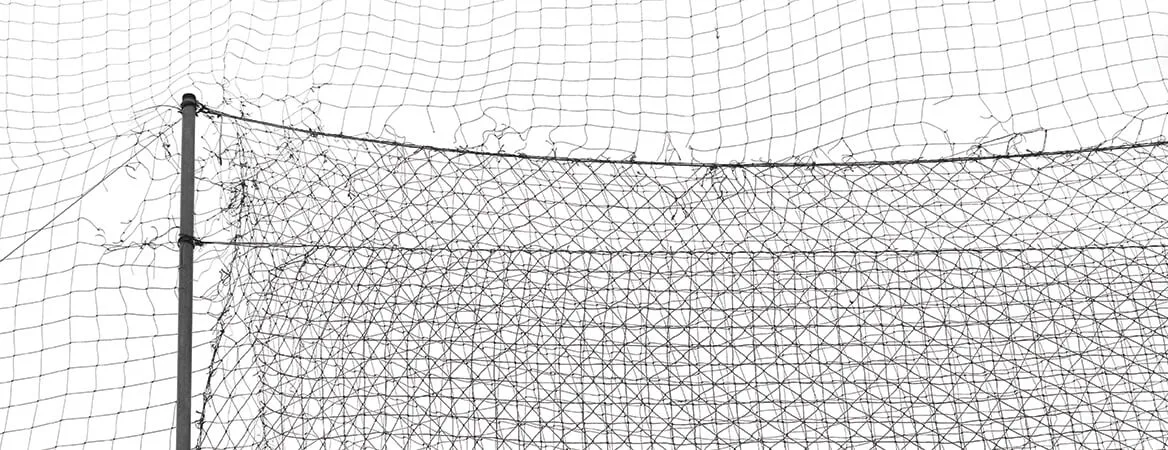

Spring cleaning is the perfect time to get outside and assess your business's netting systems. Regular maintenance can prolong the life of your netting, saving you money in the long run. But where to start? Let's dive into it.

Whether used for safety or game purposes, netting systems play a critical role in many businesses. Like any other asset, they require proper maintenance to ensure optimal performance and longevity.

Each season brings a unique set of challenges for netting. Winter can be particularly harsh, with freezing temperatures causing materials to contract and potentially leading to damage. Spring, however, is no walk in the park either. Increased sunlight exposure, fluctuating temperatures, and increased activity can all put strain on your netting systems.